Nov. 15, 2023

Rockin’ and rollin’ with tricky waste materials

Mid America Paper Recycling works with its partners to support their growth and recycling success by saving them space, time, and money. That often means providing them with innovative ways to meet their recycling challenges with paperboard, paper, corrugated, plastic, and even wood waste at a profit. We find homes for some of these trickier paper stocks, board grades, and other difficult-to-handle materials, clearing valuable space in their facilities and also making the spaces safer.

“Large rolls of converted paperboard material can be considered no longer good for a variety of reasons,” explains Jake Meszaros, National Sales Manager. “We use creative methods to get them sold. For example, we had a good cleanout of recyclable roll materials at a converter of corrugated products and protective packaging in the Northeast. They needed to remove preprinted kraft rolls and rolls of recycled kraft linerboard averaging about 50 inches in diameter and as high as 80 inches from inventory because they were obsolete, damaged, or were no longer the sizes the company was running. We were able to clear a lot of space in their facility and did a lot with those rolls.”

Space, time at a premium

The manufacturer’s main concern was saving valuable floor space and maintaining a safe work environment. “But their storage room for roll inventory continued to grow until it was too crowded, which can pose safety issues,” Meszaros remembers. “The equipment operators were maneuvering in tight spaces because they couldn’t move around the warehouse properly and as safely as required. It was a short-term challenge we knew we could resolve.”

With Mid America Paper Recycling’s help, the manufacturer was able to make room in the space and increase revenue by exporting the paperboard rolls to India to be recycled and reused as a paper product again.

Another obstacle was finding time during the manufacturer’s busy shipping schedule to load the rolls onto shipping trucks. “We helped them decide on a day each week when they could commit to loading one truck, and found a dependable, trustworthy carrier that could work with that schedule and keep the program running smoothly,” he adds. “This has been working well, without interruption, for three months now. We have already worked through their large-diameter roll inventory, and next, we’ll start handling smaller roll diameters in that sequence.”

Another bonus, the manufacturer was also able to start recycling its used wooden dieboards (hardwood die-cutting boards paperboard converters use) with Mid America’s help. “I don’t know of many companies recycling these boards,” Meszaros notes. “They’re costly to landfill and only a few at a time can be shipped in an open-top container.”

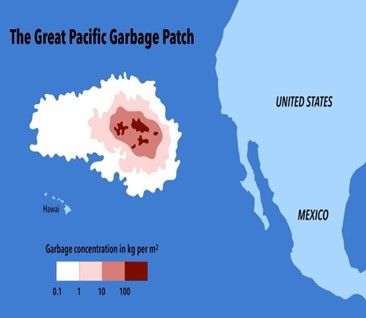

Mid America Paper Recycling found that the Northeastern manufacturer could load more volume of the dieboard waste materials on a dry van and dispose of it at a reduced cost per ton. “And we are sustainably recycling the wood, not landfilling it,” he adds. “Bit by bit, piece by piece, we are reducing their environmental impact. The Earth needs more environmental impact reduction than ever, so streamlining the manufacturer’s operation also improves its sustainability efforts. We have a good relationship with this manufacturer.”

To help you assess your difficult-to-recycle materials and upcycle your dieboards, contact Mid America Paper Recycling at 773-890-5454 or visit https://www.midamericapaper.com/.