June 7, 20224

The Largest Plastics Cleanup in History

Mid America Paper Recycling’s Brian Gaughan, Director of New Business Development, has been involved with The Ocean Cleanup, a global organization based in Delft, Netherlands, founded in 2013, that works daily and tirelessly to rid the world's oceans of plastic. The Ocean Cleanup team operates ships on the Pacific Ocean that collect plastic waste from the Great Pacific “Garbage Patch (GPGP)”, an interception/collection system for marine debris litter that ends up in the North Pacific Ocean, seas, and other large bodies of water.

“As a 30-year recycling veteran and advocate for recycling, I got involved with them in my last job,” Gaughan explains. “I find end markets for the material they catch in the Great Pacific Garbage Patch. Since then, I have stayed in contact with them and am currently working with them on options for their catch. The Ocean Clean Up has a strong team, but they rely on third-party support for their cause. The end goal is to collect the plastic waste from the ocean and incorporate it back into products supporting companies produce.”

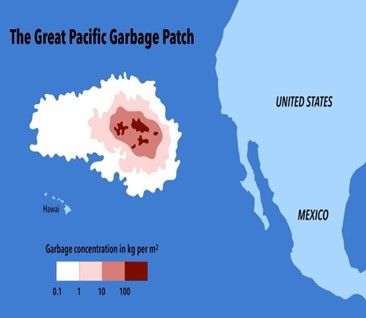

Spanning the waters from the West Coast of North America to Japan, this floating waste dump is massive. It occupies an area double the size of Texas, triple the area of France or Thailand, and is estimated to contain about 100,000,000 kilograms of plastic debris. Trillions of pieces of plastic pollute our oceans today, and the problem is worsening.

“Plastic recycling and (landfill) diversion is a major challenge in the U.S. today,” Gaughan points out.

“This plastic has a devastating impact on marine wildlife and ecosystems,” The Ocean Cleanup states on its website. “Plastics can persist for many decades, continuously degrading into microplastics. These can be ingested by wildlife and later enter the human food chain. Plastic pollution is a global crisis requiring urgent action.”

The Garbage Patch comprises the Western Garbage Patch, located near Japan, and the Eastern Garbage Patch, located between the U.S. states of Hawai'i and California. The circular motion of the whirling water draws debris into this stable center, where it becomes trapped. For instance, a plastic water bottle discarded off the coast of California takes the California Current south toward Mexico. There, the bottle may catch the North Equatorial Current, which crosses the vast Pacific. Near the coast of Japan, the bottle may travel north on the powerful Kuroshiro Current. Finally, the bottle can travel eastward on the North Pacific Current. The gently rolling vortexes of the Eastern and Western Garbage Patches gradually draw in the bottles.

Acting as an independent supporter of the project, Gaughan assists The Ocean Cleanup in advancing their cause, spreading the word about what they’re doing, and hopefully engaging more businesses that can assist in their work. “I help find processors that can take the ocean catch and separate the rigid plastics from their nets,” he says. “I also find U.S.-based compounders that can turn the plastic waste into pellets that can be resold to the companies that invest in and work with The Ocean Cleanup.”

A nonprofit environmental engineering organization based in the Netherlands, The Ocean Cleanup has been working for over 10 years, researching, extracting, intercepting and monitoring plastic pollution in oceans and rivers globally – removing millions of kilograms of waste to date. Funded by environmental foundations, automakers, top global beverage manufacturers, and many other partners, the group’s ultimate goal is to clean up 90 percent of floating ocean plastic waste by 2040.

The group also develops and scales up technology to extract plastic waste from the oceans. To achieve this objective, it uses a dual strategy of intercepting plastic in rivers to cut the inflow of waste and clean up what has already accumulated in the ocean and won’t go away by itself. “When the oceans are clean, we can capture the waste in rivers before it can reach the ocean,” the organization states. This is a crucial year in which we aim to show the world that our solution is ready to clean the entire GPGP. With the right support, we can scale up to a fleet of systems and get the job done. ”If it can achieve its desired performance levels, it says this year, it will be able to prove that its technology is ready for scale.

But the results don’t happen overnight. “We calculate it will take 20 years to rid the world’s oceans of plastic,” the group adds. “Therefore, we look for long-term partnerships with those who want to make a genuine and sustained commitment to our mission, create a legacy for themselves, and be part of the movement of those solving one of the biggest environmental problems of this era.”

As such, The Ocean Cleanup depends on several partners that help to accelerate its impact and achieve its long-term mission. The organization receives support from an array of robust partners and funders from academia, research and cultural entities, equipment providers, and nonprofits to multi-year global sponsors equipped with the resources, knowledge, expertise, and networks from many sectors that reuse the plastic materials to produce their own new products, accelerating the programs in different locations. These are just a few examples of partners who have joined the mission. The partners also conduct vessel operations and manage logistics, provide the deployment of interceptors, engage and mobilize industry from companies worldwide and so much more. In addition, donations help fund their research, development of technology and engineering and the execution of cleanup operations.

For Mid America Paper Recycling’s Gaughan, this is a passion project. “The U.S. recovery rate for plastics is 9 percent, which needs to change. I am involved with several projects trying to change this dynamic. I feel they are the right thing to do. I do not approach it from a profit perspective, but more as a way to help further the success of a worthy cause.”

For more information on Mid America’s other projects, visit our blog page at https://www.midamericapaper.com/blog. For more information on The Ocean Cleanup, including ways to support the organization, visit www.theoceancleanup.com.