Sept. 19, 2023

Mid America Paper Recycling at Pratt Industries--LH

Pratt Industries Opens Sixth 100-Percent-Recycled Paper Mill and State-of-the-Art Box Plant

Mid America Paper Recycling’s CEO Don Gaines and David Surdyk, National Sales Manager, enjoyed the grand opening of Pratt Industries, Inc.’s $700-million, 1.1-million-square foot paper mill, and corrugated box production facility on Sept. 14. The technologically advanced paper mill in Henderson, Ky., which is equipped with a new corrugator, will save the equivalent of 25,000 trees each day – that’s more trees than are in New York City’s Central Park – according to the company. The plant is a 100-percent-recycled facility.

Don Gaines, CEO of Mid America Paper Recycling, (left) talks with

Anthony Pratt, Executive Chairman of Pratt Industries (right).

“This is a very proud day for our company because this investment represents a major part of my recent pledge to the United States Ambassador to Australia, Caroline Kennedy, to invest $5 billion in recycling and clean energy infrastructure in the U.S. over the next 10 years,” said Pratt Executive Chairman, Anthony Pratt. “This will help reduce landfill, cut methane gas emissions, and create green-collar American manufacturing jobs as championed by President Biden.”

Pratt has also built six of the last eight paper mills located in America – all producing only 100-recycled paper. “This factory will employ 325 Kentuckians in well-paying, green-collar, manufacturing jobs,” Pratt said. The company now operates 72 factories across more than 25 states, and has created 12,0000 American “green” manufacturing jobs, making it the largest Australian employer of Americans, added Pratt.

Mid America Paper Recycling shares the same interests as Pratt Industries to help our suppliers close the loop and recycle their used corrugated and paperboard boxes. This helps increase their sustainability and helps the environment.

Says Surdyk: “Pratt has multiple mills, boxmaking plants, and recycling centers to support their mills. They are unique because in recent years, they have started new paper mills from the ground up. They are also unique in their ability to use a high percentage of Mixed Paper to make boxes.”

Landfill avoidance

The new paper machine in Henderson is more than twice the length of a football field, and will produce 1,500 tons of 100- percent-recycled paper every day, saving the equivalent of over 25,000 trees every 24 hours. The paper will then be made into corrugated boxes at Pratt’s converting plants across the country, including the new Henderson facility on the same site. Every ton of recycled paper manufactured in Henderson will save more than 3.3 cu. yards of landfill, 7,000 gallons of water, 4,000 kW. hours of electricity, and 1 ton of carbon dioxide. Twenty percent of the mill’s output will come from discarded paper and Old Corrugated Containers (OCC). That’s where Mid America Paper Recycling comes in. Mid America Paper Recycling carefully sources, sorts, and ships loads of quality recycled OCC to their mills, so it can be profitably recycled instead of ending up in landfills.

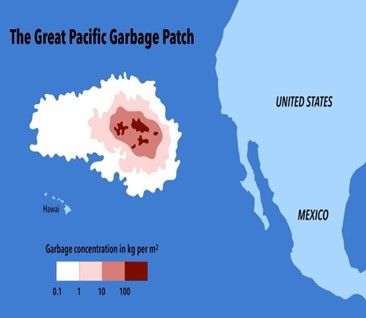

“We are transforming America’s recycling and manufacturing sectors through these initiatives,” Pratt emphasized. “We’re actually in the landfill avoidance business which is good for greenhouse gas reduction as well because as things decay in the landfill, they produce methane gas which is 84 times worse for climate change than carbon dioxide,” stated Pratt. “So recycling is an important weapon against climate change.”

More than 700 guests attended the facility opening, including Gaines and Surdyk. “The mill is so impressive,” Gaines remarked. “The plant recycles a wide range of materials that are collected in its residential, community, commercial, and industrial recycling programs. Recycling various types and grades of paper is essential to building a circular economy.”

“Don and I enjoyed the open house,” Surdyk adds. “From a mill tour to the opening ceremony featuring speeches from Pratt owner Anthony Pratt, Ambassadors of Australia to the U.S. and the U.S. to Australia, and Lonnie Ali, as well as a reception to catch up with many familiar industry faces, the day was all made possible by a fantastic and generous host.”

Experienced in working with client partners with a national and international footprint, Mid America Paper Recycling prevents corrugated and other paper waste from ending up in landfills and helps its partners earn revenue while they enjoy further progress in meeting their sustainability goals. Just like we do for clients with our paper and plastic recycling services.

To get a consultation and learn how Mid America Paper Recycling can help you better reach your recycling goals, talk to us at

773-890-5454.