June 13, 2023

A Purpose to Repurpose Under One Roof

Diverting post-consumer and post-industrial waste otherwise destined for landfills, Continuus Materials upcycles paper and plastic waste into composite roof covers.

Mid America Paper Recycling has discovered a unique way our friends at Continuus Materials’ plant in Des Moines, Iowa, are taking discarded paper/plastic raw materials and upcycling them into high-performance, engineered building products like Everboard™, a high-performance composite roof covering. Harnessing the power of circular thinking, Continuus Materials upcycles millions of pounds of discarded paper/plastic that would otherwise be disposed of in landfills.

Motivated by envisioning a world without waste, Continuus Materials produces Everboard by transforming post-industrial and post-consumer plastic and paper that would otherwise pile up in landfills into a highly resilient and infinitely recyclable roof cover board. The company says Everboard delivers decades of protection. Built with durability, the roof board is simple to install and is easier to work with than most gypsum-based roof boards.

Mid America Paper Recycling is always looking for ways to recycle paper and plastic items into something reusable. Continuus Materials accepts assorted paper and plastic waste like low-density polyethylene film, high-density polyethylene bottles, mixed paper, and paperboard cartons from a wide range of supply channels that meets its exacting standards. Soon, Mid America Paper Recycling will furnish it with homogeneous materials. The raw material is then sorted and the Des Moines plant shreds it before using pressure to press and form it into the long-lasting Everboard roof board product.

“For every 1,000 square feet of Everboard roof cover board that we produce, 2,000 lb. of post-consumer and post-industrial paper and plastic are diverted from landfills,” the company explains. “Everboard can be fully-recycled into new roof cover board, which is circularity at work.”

Recognizing sustainability isn’t about going it alone, Continuus Materials met Mid America Paper Recycling at an industry conference last fall. Like Continuus Materials, Mid America Paper

Recycling develops recycling solutions with partners ranging from small businesses to large multinational corporations. “We are always coming up with new value-creation insights we share with our clients and supplier-partners,” says Mid America Paper Recycling President Paul Pirkle. “With our national reach and vast industry connections, we can assist businesses in diverting tons of their waste from landfills, and we can help you, too.”

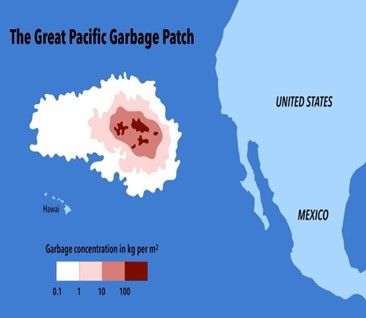

The work the two companies do is important: Continuus Materials estimates that 10 million tons of it are dumped in oceans each year. At least 90% of the trash floating in our oceans is made of plastic. More than 380 million tons of plastic waste is produced worldwide every year, but less than 9% of it gets recycled.

Mid America Paper Recycling markets assorted waste materials to buyers, saving them time, and can help them earn money on their waste, which can transform paper and plastic recycling from an expense to a revenue stream. “Like Continuus Materials, working with us helps our business partners meet their goals on the path to sustainability.”

To learn more about Continuus Materials, visit https://www.continuusmaterials.com. To help you assess your dieboard upcycling opportunities, contact Mid America Paper Recycling at 773-890-5454 or visit https://www.midamericapaper.com.