May 2021 State of the Market, from Paul Pirkle, President of Mid America Paper Recycling

But lately, new and expanding capacity is on the horizon for recovered paper markets in North America. From 2018 to 2023, more than 5 million tons per year of new old corrugated containers (OCC), mixed paper consuming capacity and 1 million tons per year of recycled pulp could come online within North America, according to data compiled by the Northeast Recycling Council (NERC), Brattleboro, Vt. Some 70 percent of the volume of material recycled in the U.S. comes from commercial and industrial sectors, and that material tends to be cleaner and can be processed to higher grades with greater marketability. Such materials must be consumed, repurposed and converted into new products. At Mid America, we continue finding market demand for these materials every day.

Materials recycling is critical to the U.S. economy. Another key advantage in the U.S. is recycling’s importance as an economic engine and job creator. The recycling industry directly employs more than 164,000 Americans in jobs averaging $73,000 in wages and benefits annually, while generating $110 billion in economic activity and $13 billion in federal, state, and local tax revenue, reports the Institute of Scrap Recycling Industries (ISRI), Washington.

We at Mid America Paper Recycling have been proving these newsbytes for years. The Bureau of International Recycling (BIR) estimates that more than 40 percent of manufacturers’ raw material needs around the world are met through the recycling of obsolete, off-spec and end-of-life products and materials. We’ve known it all along. So Mid America Paper Recycling is taking steps to communicate more about our efforts, document our ideas and expand our communications reach, and we’re making progress on all these fronts, starting with new developments on our website and social media platform.

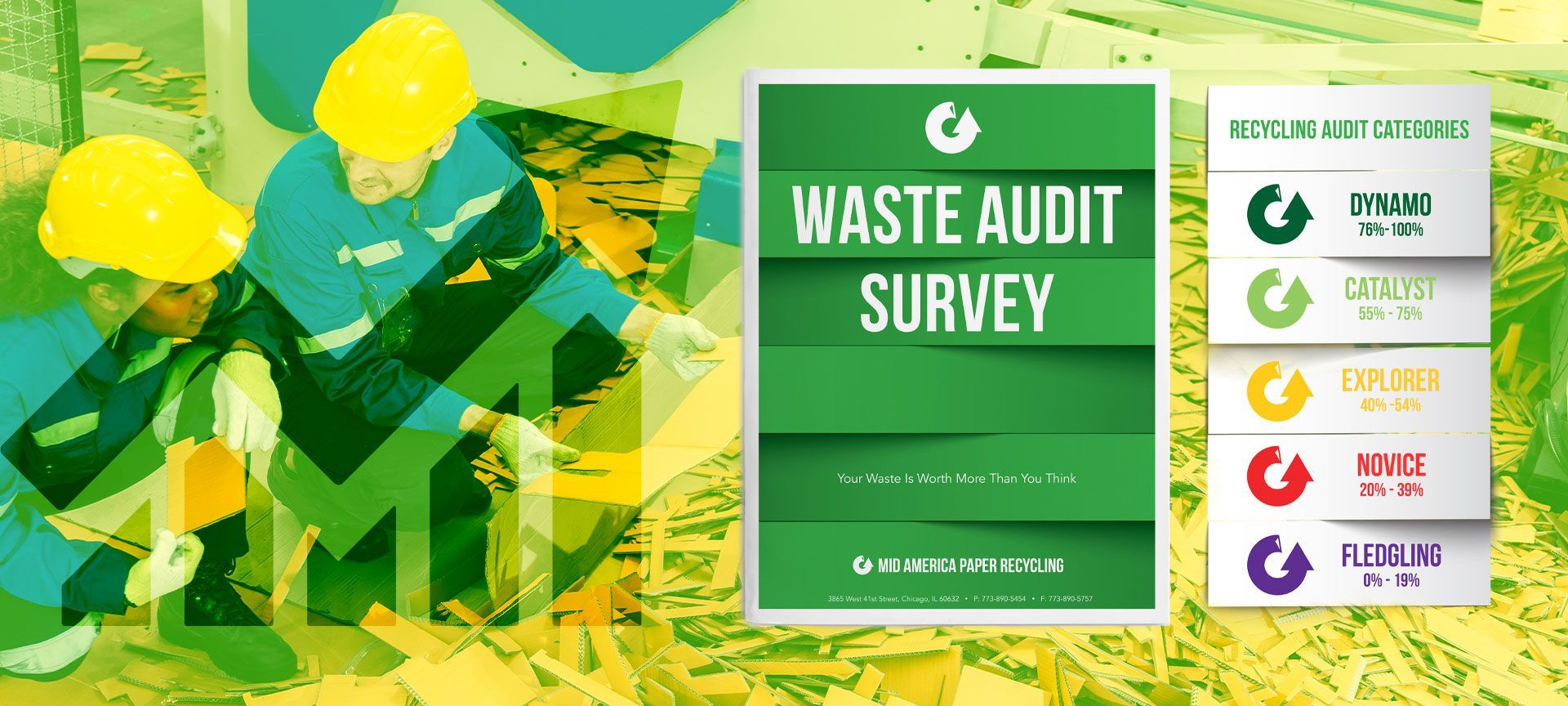

You’ll find more news from our “Waste Into Wealth newsletter, industry and company updates, recycling industry advancements, personnel profiles, trends, equipment updates and more, including more details about our focus on continuous improvement and our Waste Audit service.

Change is a constant in most industries, and we are especially in the business of change, transforming the old into new. We’re passionate about it and can’t wait to show you how we’re generating more value for our strategic partners. So, give us a call at 773/890-5454 (https://midamericapaper.com/contact/) and find out why Mid America Paper Recycling is at the forefront of post-industrial paper recycling.

Leave a Reply