MAPR Blog--Light Load Charges

April 13, 2022

Don’t Come Up Short: Avoiding Light Load Charges

Recycling logistics teams must meet new challenges motivated by transportation costs savings and ecological efforts. Optimizing trailer load pack patterns can help.

If there was ever a case where weight loss was a problem, this is it: Right now, like everything else, logistics and shipping costs are quickly rising for paper waste suppliers that ship bales of their recyclable paper waste mill-direct. Trouble is, trailer loads of the recyclable paper waste that don’t hit the requisite 20-ton (40,000-lb) weight requirement set by most pulp and paper mills get slapped with what are called Light Load freight charge backs.

These charges can add up, and hinder recycling operations from delivering real value to customers. Monitoring them regularly, as well as the weights of trailer load waste is a must. That’s why Mid America Paper Recycling advises its supplier partners to be as accurate and efficient as possible when baling their paper waste. It can make a powerful impact on the bottom line, explains Mid America’s President Paul Pirkle.

“It’s worth reviewing any light load charges passed on by the paper mills,” Pirkle says. “Light load charges are usually assessed when a supplier’s load of paper waste -- regardless of the type of paper -- doesn’t weigh the required 40,000 pounds (or 20 tons) most mills require. The charges can be a significant drain on profitability, and can have been avoided with better visibility into the loading process.”

For example, if your mill-direct freight cost to ship a load of recyclable paperboard weighing the standard 20 tons is $1,000, and the load weighs 19 tons (or one ton less than the acceptable standard), a charge assessed to the Light Load would be $50 ($1,000 divided by 20 = $50). That charge will be assessed on a per-ton basis for every load weighing less than 20 tons. If your trailer load is two tons short, a Light Load charge would be $100.

“We always caution companies about weight requirements for shipping trailer loads,” Pirkle explains. “Paper waste suppliers should focus on hitting the 20-ton or 40,000-pound weight target, no matter what type of paper waste they’re shipping. Otherwise, they will be charged back for any loads weighing less, divided by their cost of shipping the load into the site. With freight costs increasing in general, these charges are intensified.”

Increasing baling efficiency

There are several reasons a load can be underweight. Mid America advises suppliers to examine their truck loading patterns with a couple of “smart” solutions that will boost the efficiency of loading operations and maximize bale weights. By working smart, you can increase cube efficiency in the trailer, higher accuracy, worker safety, and customer satisfaction with Mid America Paper Recycling’s assistance.

There are a few important considerations suppliers can use with underweight trailer loads, Pirkle says. “Check to make sure that you are regularly maintaining your baling equipment with the recommended preventive maintenance and also confirm that your baler is achieving the best bale compression possible per the manufacturer's specifications.”

Bales weigh between 900 and 1,500 lb. Most baling systems available on the market are easily able to compress (or densify) a bale of paper waste material into a tight, compact unit weighing 1,250 lbs. or more.

“If your bales weigh less than 1,000 pounds, they can be too light and could cause an entire trailer load to be short of the target weight (40,000 lbs.),” Pirkle says. “The baler is one of the first things we look at when we hear that trailer loads are under weight. Examining the baling procedures and inspecting the baling equipment to ensure that it’s properly maintained are important. Make sure the equipment is working properly and operating with the correct compression.”

Second, if the baler(s) is working properly, and the loads still aren’t hitting the target weight, check the loading pattern. In the haste to get a trailer on the road, bales of paper waste might be loaded incorrectly.

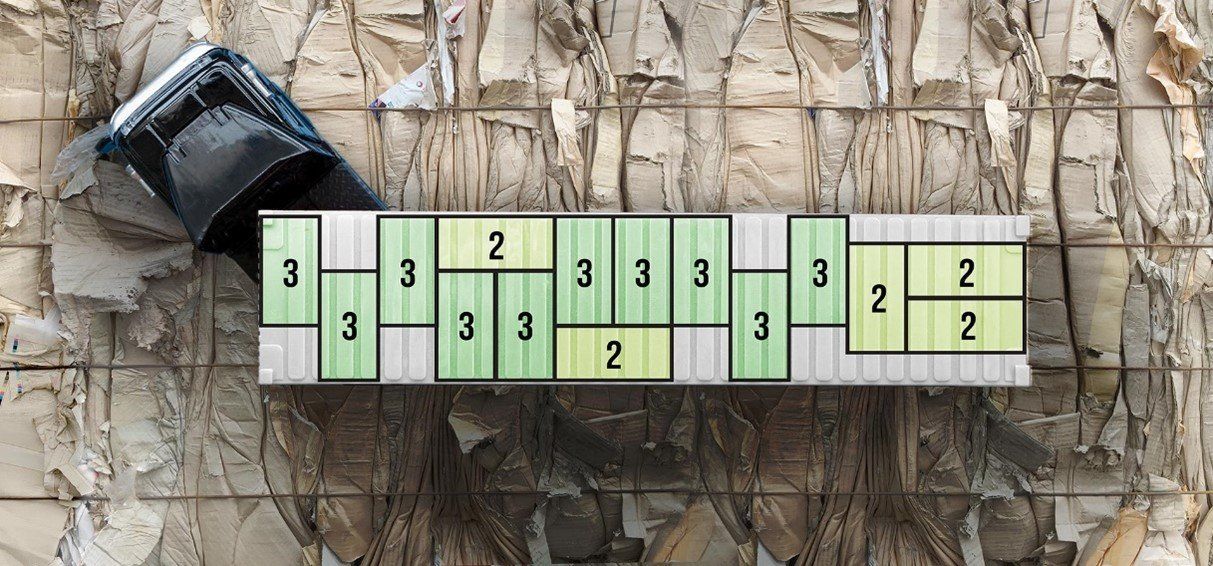

“Loading patterns are the next thing we look at,” Pirkle mentions. “Share what your bale patterns looks like. We will then confirm that the correct pattern is being used and that the bales are being properly, and safely, loaded into the trailer so the bales will be received by the mill properly.”

The chart above shows a trailer loading pattern Mid America custom developed for a supplier. It is imperative to load the last two bales in the truck perpendicular to the other bales for safe unloading.

Optimizing pack patterns

A standard 53-ft.-long truck trailer should hold 36-39 bales, Pirkle adds. If that checks the box, and the bales weigh what they should and are being loaded into the truck according to the correct pattern, what if they still come up underweight?

“Then, we look at the rest of the operation,” Pirkle replies. “In instances where we visit the supplier’s site to determine the cause of the light loads, we check their baler’s performance and re-examine the loading pattern. We may also find something else within the operation that might need correcting. In most cases, we’ll be able to improve the loading pattern design for more efficiency. We also have the supplier post diagrams of scaled drawings of the pack pattern and loading instructions for easy reference whenever they need it. We then load a trailer using the new format, to see how many bales will fit.”

Mid America may suggest that suppliers invest in a scale to ensure they’re getting accurate weights, Pirkle points out. “Light Load charges can be completely avoided. Checking the loading pattern and ensuring your baler is well maintained will ensure that you are continually turning waste streams into profit streams.”